Link to: Get in touch

Download our Exclusive Whitepaper

AR Waveguides: Optimized Cutting Processes for Transparent Materials with Laser Technology

AR (Augmented Reality), MR (Mixed Reality), XR (Extended Reality), HMD (Helmet-Mounted Display), and HUD (Head-Up Display) are acronyms on everyone’s lips during the past few years. This whitepaper explores how laser technology can be used in the production of AR waveguides – especially regarding cutting processes.

The first devices with augmented or mixed reality functions arose mainly in the prosumer (or industrial) segment. As the industry is transforming from the explorative phase of R&D towards focussing on prototypes, questions regarding automation, stable processes, lifetime, and reliability arise.

While the technological challenges of AR devices are more in the foreground at the moment, addressing their economic challenges will be increasingly important. As AR device production numbers might finally rise to billions of units, the supply chain will be driven by cost efficiency. In order to achieve this, AR device manufacturing requires a high level of automation combined with fast and stable processes.

Waveguide Combiners on High-index Glasses

Waveguide combiners are a promising technological solution that is making up for the shortcomings of current AR devices. Unlike conventional optics like free space combiners, waveguides have the potential to deliver the performance expected by the users in a sleek form factor.

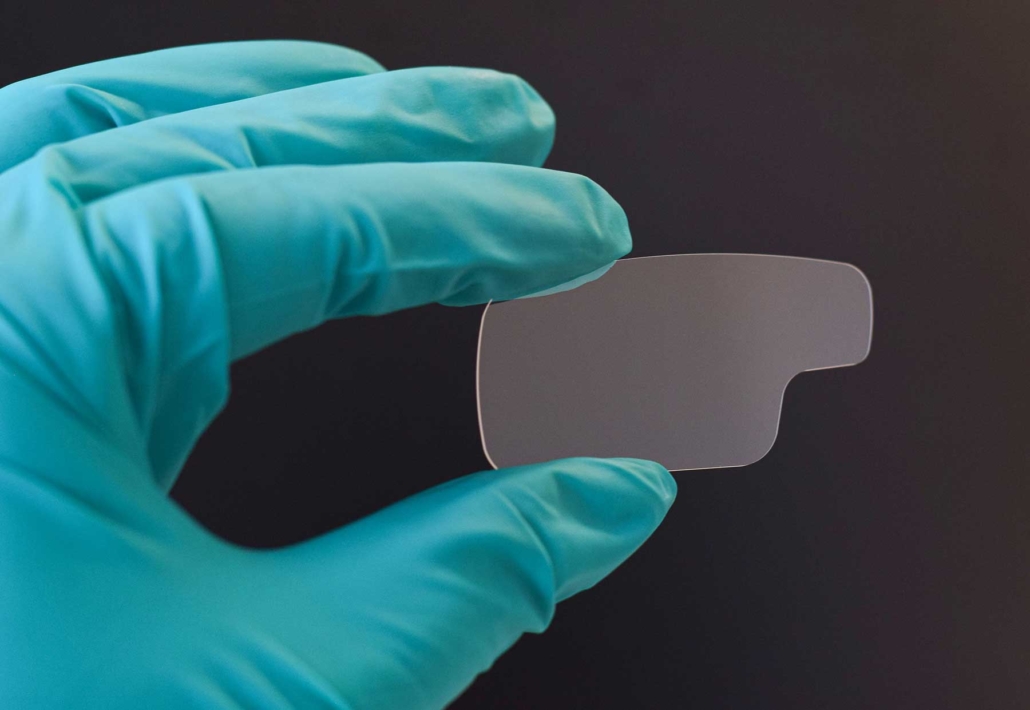

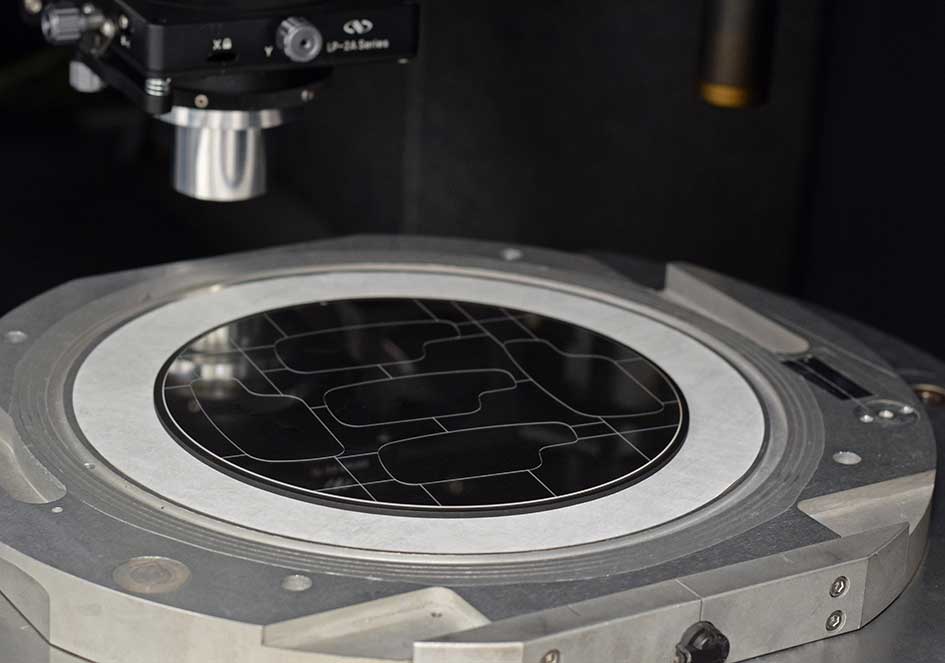

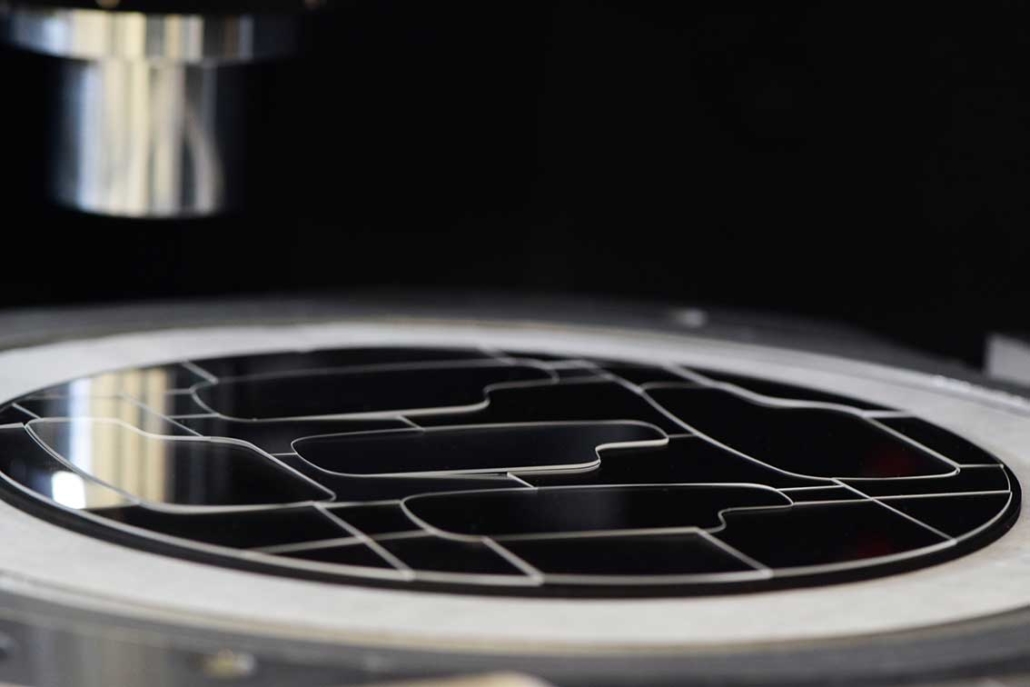

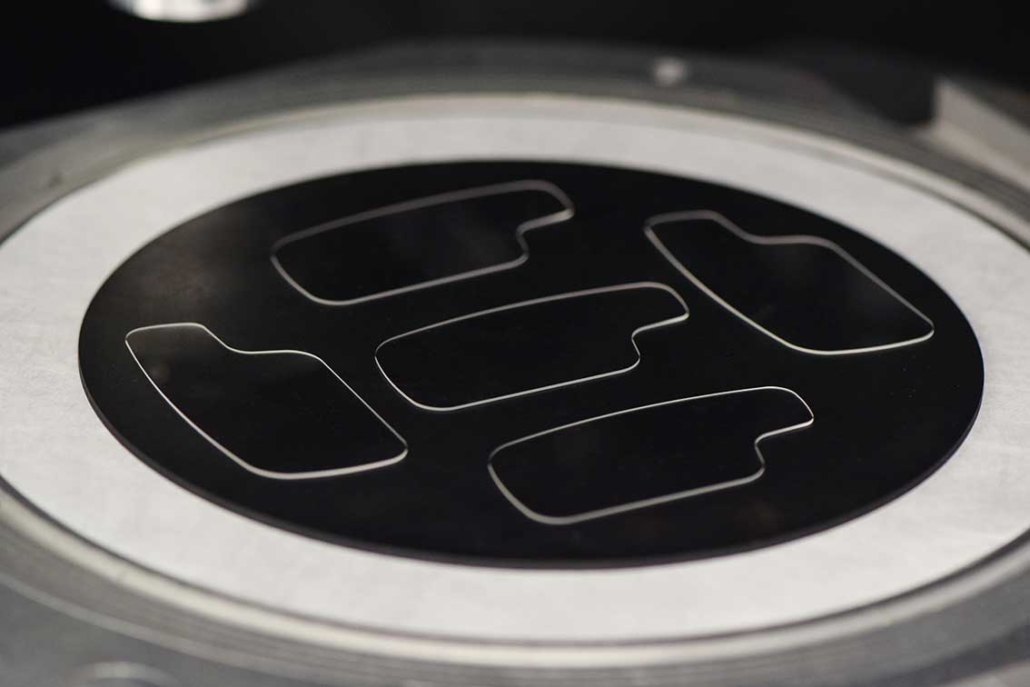

AR waveguide combiners typically use substrates made of high-index glass. Thus, in order to ensure a maximum angle of internal reflection of the waveguide and a maximized Field of View. Injection and extraction gratings are often made by index-matched nanoimprint lithography resins. An anti-reflective coating can be applied to the opposite side of the substrate. Therefore, depending on the glass, resin, and coating type, the cutting process of AR waveguides needs to be optimized accordingly to achieve maximum cutting quality. The high-index glass wafers are the basis for high-volume, next-generation AR waveguide manufacturing.

In this whitepaper, you will learn what is required to optimize the cutting of eyeglass pairs from raw high-index glass wafers in order to make the application fit for mass production of AR waveguides. Among other things, it discusses the importance of correctly setting the laser parameters for cutting the AR eyepieces and the interaction of the laser sources with the machine. In addition, the whitepaper explores the essential core parameters, the right choice of laser sources, and what more is needed to make the application economical.

Get Access to the Exclusive Whitepaper on

Waveguides in AR Devices

To receive our whitepaper Optimized Cutting Processes for Transparent Materials with Laser Technology, enter your contact data so that we can send you a download link. Your data is safe with us – for details, read our privacy statement.