Link to: Get in touch

Market Characteristics – Specific Challenges

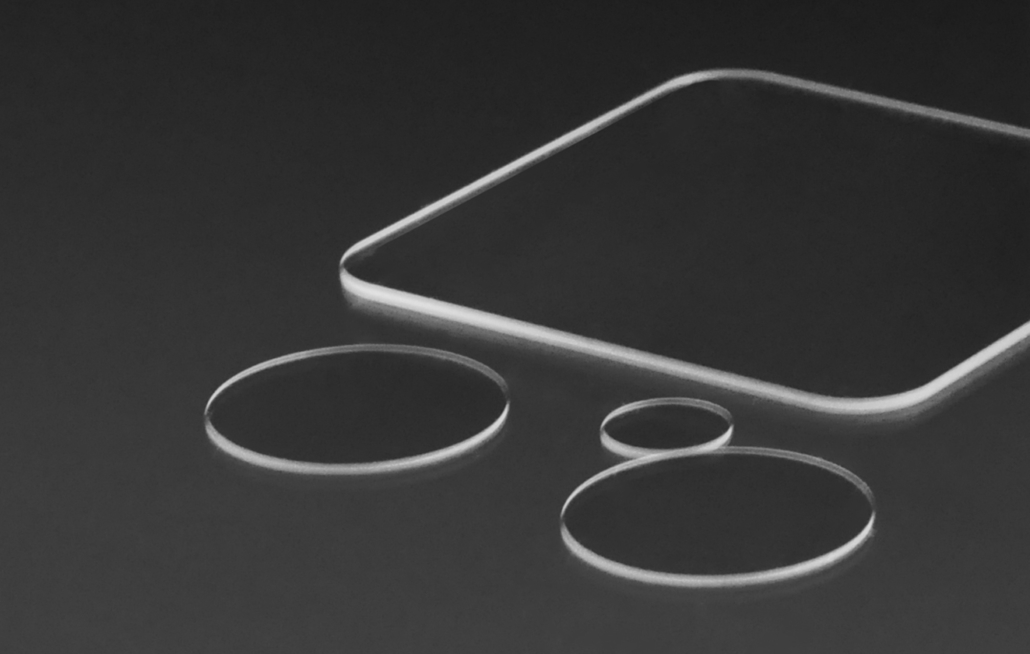

The use of glass as optical devices has become more common within the past few years. Glass is widely used for filters, where optical coatings are applied on at least one side of the substrates. In the past years, laser technologies have been established for industrial processing of glass materials. Laser processing of glass enables rapid, highly precise and highly reproducible processing of glass substrates.

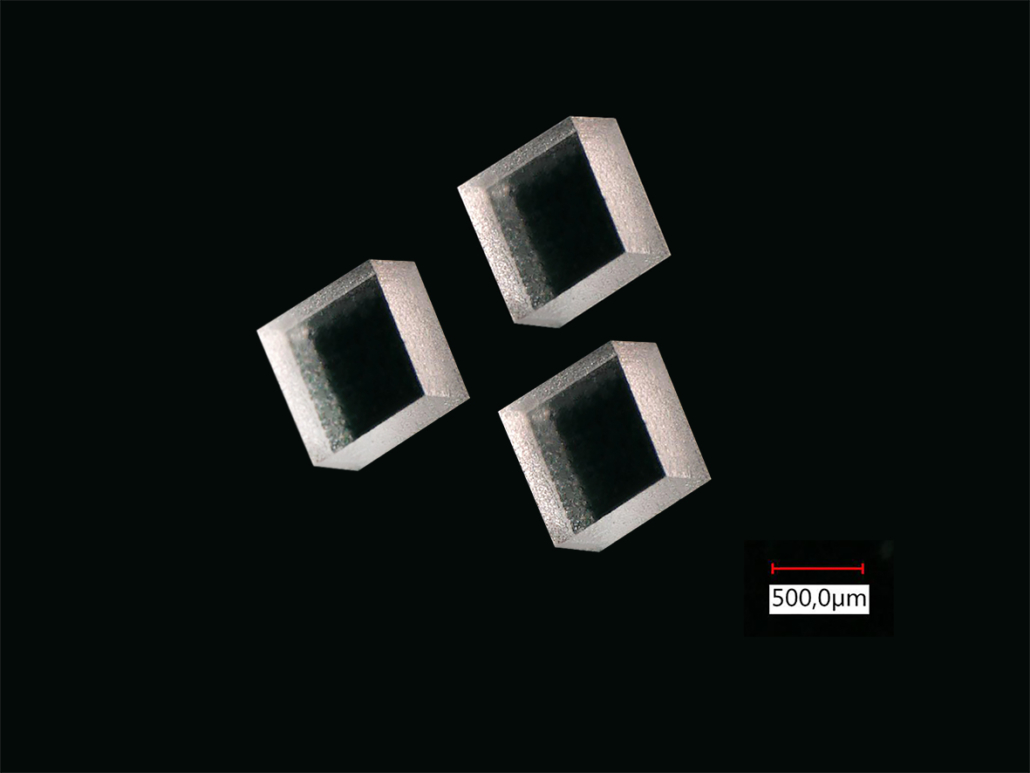

Other applications are microlens arrays or other kinds of lenses. Last but not least diffractive optical elements are also made from glass. The mother substrates are glass wafers with dielectric coatings or molded glasses with surfaces that are not flat. Additionally, the end products often are very tiny – with sizes of only a few millimeters or even smaller. Therefore, these end products are pretty hard to handle when it comes to a fully automated process. A suitable laser processing technology for optical elements needs to address those specific requirements in an appropriate way.

Send an E-Mail to: mailto:liebers@3d-micromac.com

Contact

Please contact our expert for more information.

René Liebers

Tel: +49 371 40043-432

liebers@3d-micromac.com

Laser Processing of Coated Glass Wafers for Optical Devices

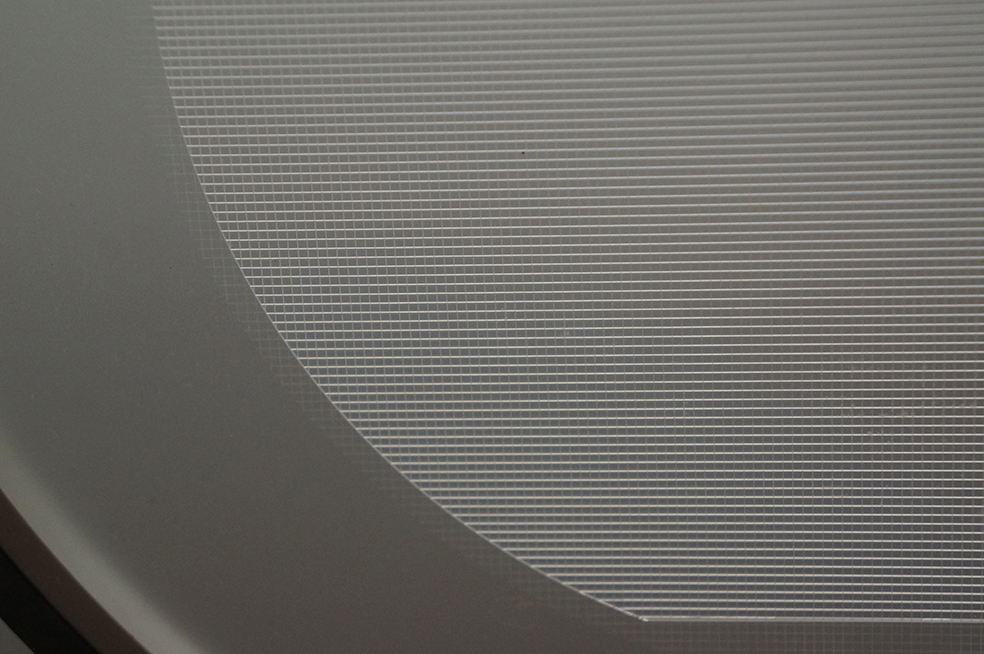

Glasses are used in a wide variety of optical devices. Raw materials are standardized wafers. Typically, these wafers are coated with dielectric coatings. These coatings are dedicated to act as filters for a specific wavelength. In addition, some wafers are patterned with microstructured stacks applied on the glass surface.

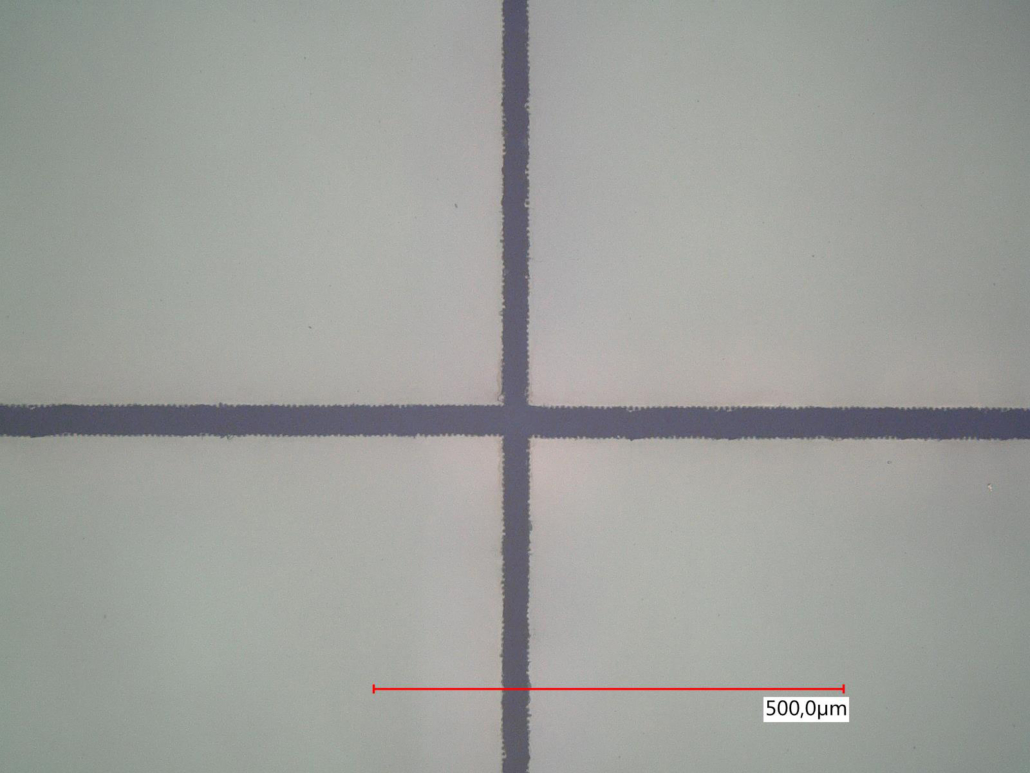

Our machines are capable of low-damage dicing of glass wafers with dielectric coatings. Using femtosecond lasers minimizes the heat-affected zone and delamination of functional layers. The process is nearly particle-free and guarantees a minimized contamination of sensitive functional areas.

The in-house developed laser process is adapted to the requirements of the components and can be alligned to the throughput demands of the customers through a customized production solution.

The optimized material flow in our systems offers the possibility to produce small quantities as efficiently as mass production. The result of short set-up times is the achievement of low production costs per component.

Our systems are capable of processing all typical materials:

- fused silica (HPFS and others)

- Borosilicate ( B33, 1737F)

- SCHOTT D263T

- Others

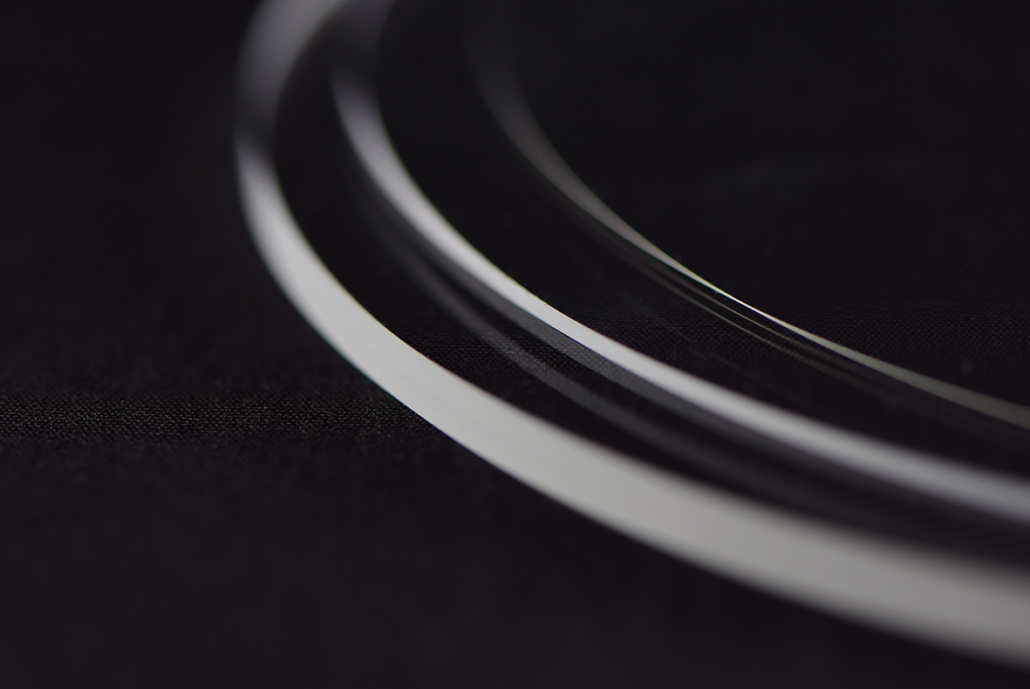

Laser Processing of Molded Glass

Very often, technical glass products are produced either directly as semi-finished products such as wafers or tubes; if special surface shapes or special geometries are required, these can also be produced by forming processes. There are primary forming processes where the end product is obtained directly from the hot glass melt by drawing, floatation, molding, rolling, pressing, or blowing the still viscous glass mass. For the production of technical optics, lenses, or lens arrays, forming processes are typically used in which cold glass raw material is reheated so that it can be processed plastically.

End products can be aspheres, free-form optics, and segmented lenses to line generators, cylinders, and cylinder lenses as well as diffractive elements. The so-called molding production processes are effective production methods, where multiple devices could be produced in parallel. The device does not require any further process steps that change the optical surface. The only critical process step is the final singulation of the devices from their preform.

A laser cutting process is well suited for this purpose because, unlike sawing, it can also be used to produce free-form shapes or radii. Regarding the layouts, one is almost completely free and new designs are possible. In addition, the production chain benefits from the absence of particles and the high edge quality of the laser process.